Taimako ta atomatik Bender HMBC2202-2203

ƙayyadaddun samfuran

| A'a. | Suna | Siga | Naúrar |

| 1 | Tsawon tsayi | 2200 | mm |

| 2 | Nisa mafi girma | 1500 | mm |

| 3 | Min.Tsawon lankwasawa | 130 | mm |

| 4 | Min. faɗin lanƙwasawa | 240 | mm |

| 5 | Matsakaicin kauri (MS, UTS410N/mm²) | 2 | mm |

| 6 | Min. lankwasawa (MS, UTS410N/mm²) | 0.35 | mm |

| 7 | Matsakaicin tsayin lanƙwasawa | 200 | mm |

| 8 | Yanayin daidaita tsayin latsa babba | Na atomatik | |

| 9 | Matsakaicin amfani da makamashi | 4 | KW |

| 10 | Girman Outlook: L*W*h | 6100 * 2700 * 2920 | mm |

ƙayyadaddun samfuran

| A'a. | Suna | Siga | Naúrar |

| 1 | Tsawon tsayi | 2200 | mm |

| 2 | Nisa mafi girma | 1500 | mm |

| 3 | Min.Tsawon lankwasawa | 430 | mm |

| 4 | Min. faɗin lanƙwasawa | 350 | mm |

| 5 | Max. lankwasawa (Bakin Karfe, UTS660N/mm) | 1.8 (+-90 °) | mm |

| 6 | Max. lankwasawa (karfe, UTS410N/mm) | 3 (+-90 °) | mm |

| 8 | Min. lankwasawa (aluminum, UTS120N/mm) | 0.35 | mm |

| 9 | Matsakaicin tsayin lanƙwasawa | 300 | mm |

| 10 | Yanayin daidaita tsayin latsa babba | Na atomatik | |

| 11 | Matsakaicin amfani da makamashi | 12 | KW |

| 12 | Nauyi | 32 | T |

| 13 | Girman Outlook: L*W*h | 6300*5500*3300 | mm |

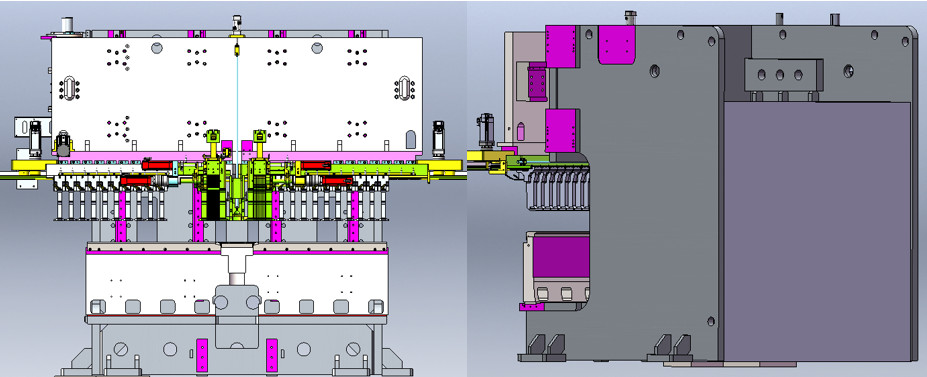

Halaye da babban tsari

A cikin sharuddan inji zane da kuma masana'antu, He Bei Han Zhin CNC Machinery Co., Ltd.ya fi mayar da hankali kan abubuwa masu zuwa:

1.Kasuwancin kasuwa na neman aiki da kuma adana kowane dinari ga masu amfani;

2.Very abin dogara da daidaitattun ra'ayoyin ƙira;

3.High ingancin albarkatun kasa, fitar da sassa da kuma m aiki fasahar;

4.More girmamawa akan dacewa da aminci na amfani da kiyayewa;

5.Low mai kulawa da ƙimar kulawa a cikin masana'antar guda ɗaya.

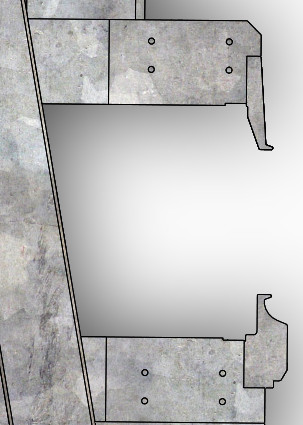

firam

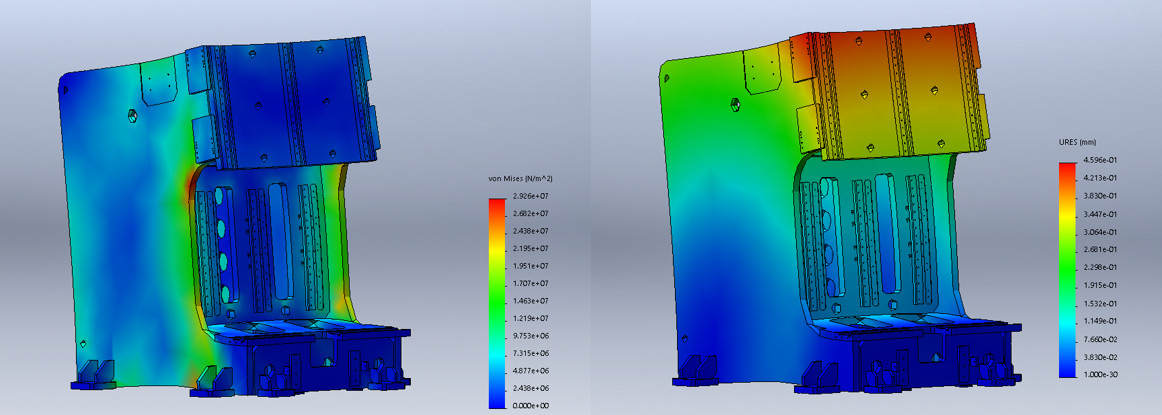

A. Ƙirƙirar ƙirar ƙayyadaddun ƙayyadaddun ƙayyadaddun abubuwa masu girma uku: bisa ga ƙaƙƙarfan samfuri mai girma uku da aka haɓaka kuma aka tsara, kafa ƙaƙƙarfan ƙirar ƙira mai ƙarfi don ƙididdigewa.Samfurin yayi la'akari da mahimman abubuwan haɗin gwiwa akan haɗin watsawa.Ana watsa ƙarfin zuwa tallafi ta hanyar sassan haɗin kai, sa'an nan kuma ana gudanar da nazarin ƙarfin goyon baya.

B. Binciken sakamakon bincike na tsaye: saboda jinkirin aiki da sauri, ana iya danganta ƙarfin bincike ga matsalolin tsaye.Dangane da nauyin matsi na farantin karfe da nauyin lanƙwasa a tsaye a tsaye na shugaban mai yanke, an nuna sakamakon damuwa da nakasar a cikin hoton da ke ƙasa.Matsakaicin damuwa yana bayyana a makogwaro na fuselage, matsakaicin matsakaici shine 21.2mpa, matsakaicin nakasawa yana bayyana a saman ƙarshen fuselage, kuma matsakaicin nakasar shine 0.30mm.

Dangane da sakamakon ƙididdigar ƙarancin ƙima na firam, an zaɓi ƙarfe Q345 azaman kayan;Carbon dioxide kariya waldi;Gudanar da maganin zafin jiki don kawar da damuwa da walda ke haifarwa;Don tabbatar da daidaito, kwanciyar hankali da tsayin daka na kayan aiki don aiki na dogon lokaci.

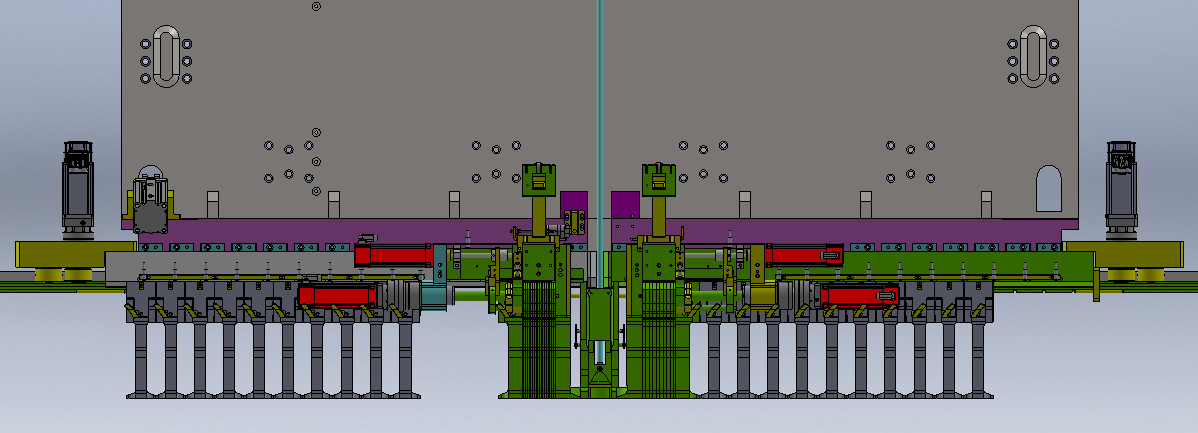

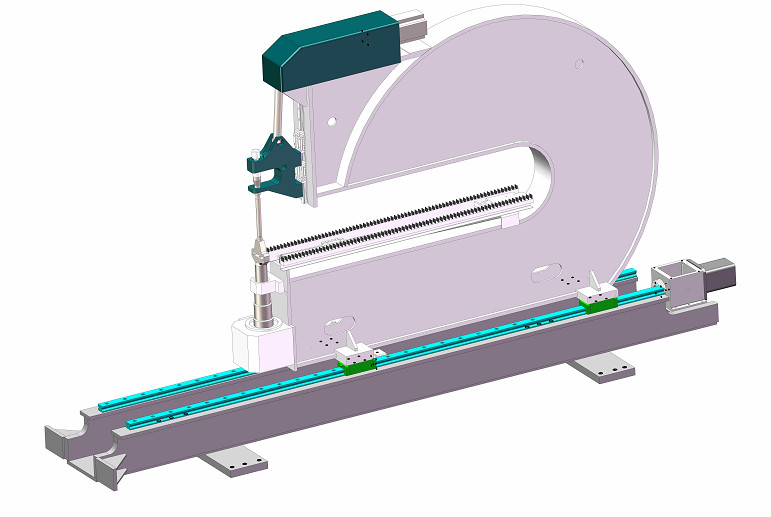

Babban rago

Wannan bangare ne yafi hada da rago, high karfin juyi gubar dunƙule, reducer, jagora dogo, servo motor, da dai sauransu Babban drive ne sarrafa ta servo motor, da kuma kula da yanayin ne servo synchronous iko, wanda zai iya yadda ya kamata tabbatar da sakawa daidaito, da sauri. gudun da kuma babban iko.Lubrication na ledar dunƙule da jagorar dogo yana ɗaukar man shafawa ta atomatik, kuma maiko shine 00 #, don tabbatar da rayuwar sabis da daidaiton kuɗaɗɗen gubar da layin jagora don aiki na dogon lokaci.

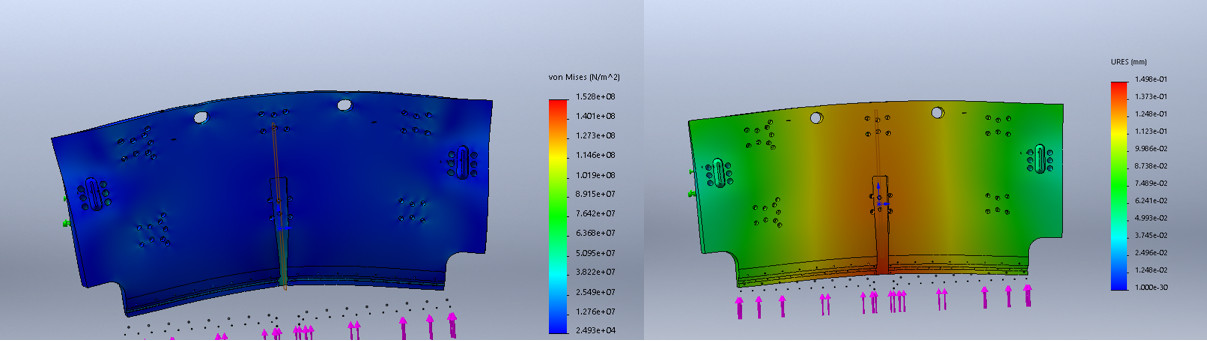

Binciken sakamakon bincike mai mahimmanci na babban faifai: matsananciyar damuwa na nephogram na tebur na sama yana nuna cewa matsakaicin matsananciyar damuwa yana bayyana a saman babban ɓangaren, matsakaicin matsakaicin shine 152mpa, matsakaicin nakasawa yana bayyana a saman ƙarshen babba. worktable, kuma matsakaicin nakasawa ne 0.15mm

Dangane da sakamakon bincike na ƙarshe na ragon, an zaɓi ƙarfe Q345 azaman kayan;Carbon dioxide kariya waldi;Gudanar da maganin zafin jiki don kawar da damuwa da walda ke haifarwa;Don tabbatar da daidaito, kwanciyar hankali da tsayin daka na kayan aiki don aiki na dogon lokaci.

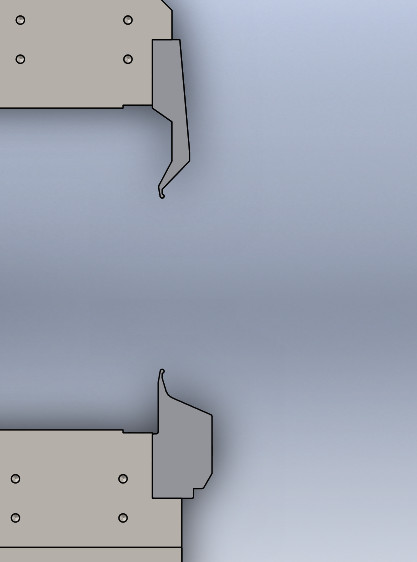

Lankwasawa naúrar

Bangaren tukin wutar lantarki na sashin lanƙwasawa yana motsa shi ta hanyar servo motor ba tare da shigar da tsarin na'ura mai ba da hanya tsakanin hanyoyin sadarwa ba, wanda ke da fa'ida mai yawa wajen rage yawan lalacewa da watsawa, kuma ya yi daidai da manufofin ceton makamashi da kare muhalli da jihar ke ba da shawarar.

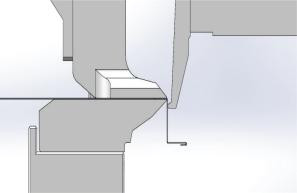

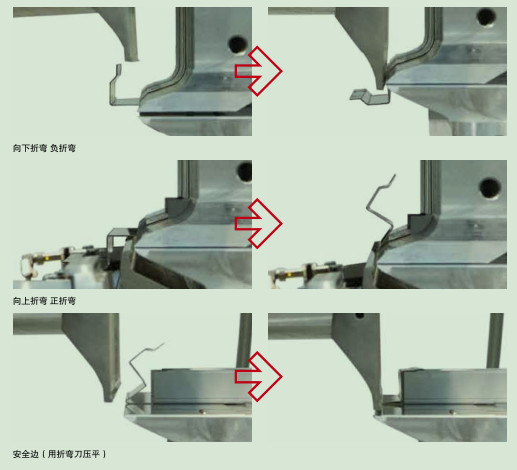

Dangane da saitin bayanan faranti, tsarin ta atomatik yana ƙididdige matsayi na wuka mai latsawa ta sama 3, yana sarrafa nisa tsakanin wuka mai latsawa na sama da wuka 4, kuma yana gyara farantin;Dangane da tsarin tsarin, ko wannan lanƙwasa yana sama ko ƙasa, sarrafa wuka mai lanƙwasa ƙananan 2 ko wuka mai lanƙwasa na sama 1 don matsawa da sauri zuwa matsayi;Dangane da kusurwoyin saiti daban-daban, dabarar lissafin kusurwar da aka mallaka tana sarrafa naushin lanƙwasa don matsawa zuwa matsayin lissafi don kammala lanƙwasawa.

Dangane da hanyoyin lankwasawa daban-daban, ana iya raba shi zuwa lankwasa kusurwa, manyan lankwasa baka, lankwasawa da sauransu.

Naúrar latsa sama

Naúrar latsa sama: ɓangaren da za a yi amfani da shi a duk sarrafa lankwasawa.HMBC full servo multilateral lankwasa cibiyar sanye take da musamman babba latsa naúrar, wanda za a iya shigar da kuma daidaita ta atomatik bisa daban-daban tsawon farantin.

Kayan aiki

An rarraba kayan aikin lankwasawa zuwa kayan aikin lanƙwasawa na sama da ƙananan kayan aikin lanƙwasawa.Ana iya daidaita kayan aikin lanƙwasawa na musamman bisa ga buƙatun abokan ciniki daban-daban.

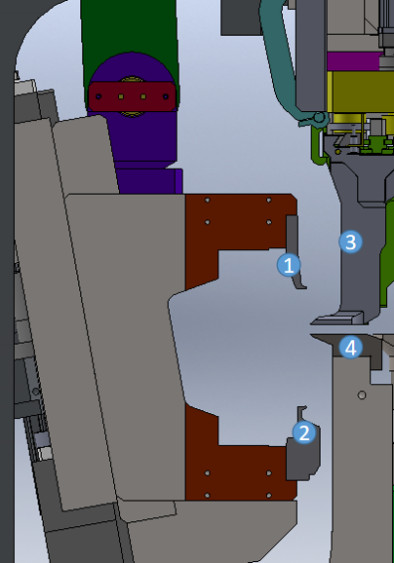

2. Sashin ciyar da faranti:

Motsi, clamping da jujjuya karfen takarda ana sarrafa su ta manipulator 1, clamp 2 da diski mai juyawa 3 bi da bi.The ciyar da takardar karfe da aka sarrafa ta servo motor a cikin dukan aiki tsari, don gane aiki da kai da kuma m matsayi, rage mataki lokaci da kuma inganta yadda ya dace.Saboda sababbin tsarin da aikace-aikacen cikakken iko na servo, a cikin dukan tsarin aiki na cibiyar lankwasawa da yawa, ƙugiya da juyawa na takarda na iya kiyaye daidaito.Don da yawa hadaddun workpieces har ma da polygonal workpieces, ci gaba da jujjuya daidaito za a iya garantin zama 0.001.

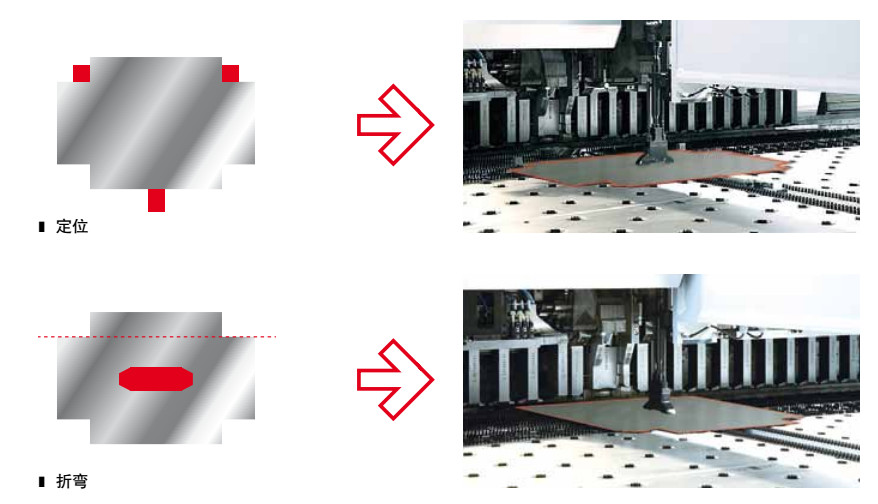

3.Plate sakawa naúrar:

Naúrar sakawa farantin ta ƙunshi fil ɗin matsayi na hagu, fil ɗin daidaitawa na dama, fil ɗin sakawa gaba da fil ɗin sakawa na baya;Matsakaicin hagu da dama na iya gano wuraren hagu da dama na farantin.Fitin sakawa na gaba da fil ɗin sakawa na baya suna sarrafa gaba da baya na farantin don tabbatar da cewa farantin yana daidai da wuƙaƙe na sama da na ƙasa, waɗanda ake amfani da su don tabbatar da daidaiton matsayi na farantin.

Na'urar sakawa farantin na iya kammala daidaitawar farantin ta atomatik kuma ta atomatik kammala lanƙwasawa da yawa a lokaci ɗaya, wanda ke rage girman lokacin sake zagayowar kuma yana sarrafa kuskuren yanke farantin a farkon lanƙwasa don tabbatar da daidaiton lanƙwasawa.

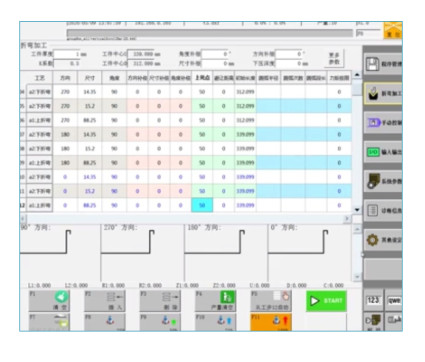

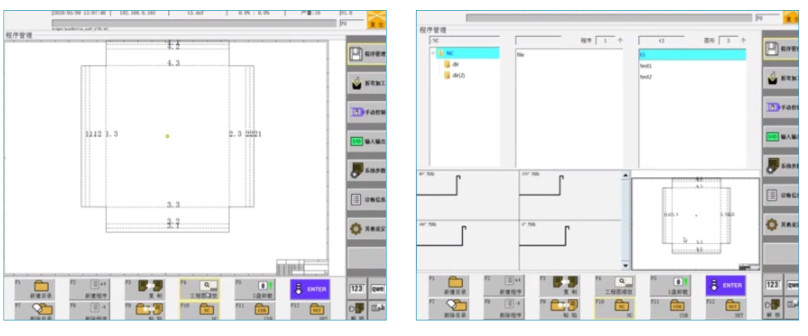

4.CNC tsarin

A: Za a iya amfani da tsarin CNC da software da aka haɓaka tare da sauri da kuma dacewa

B: Babban fasali:

a) .An karɓi yanayin sarrafa bas na EtherCAT, tare da ƙarfin hana tsangwama

b) Goyan bayan shirye-shirye kai tsaye da shigar da bayanan lanƙwasawa na kowane mataki a cikin tsari

c) Taimakawa baka lankwasawa

d) Cikakken sarrafa wutar lantarki

e) Goyi bayan aikin lankwasawa

f) Goyan bayan aikin shirye-shirye masu girma biyu

Ayyukan shirye-shirye masu girma biyu, shigo da bayanan zane mai girma biyu na DXF, kuma suna samar da tsari ta atomatik, girman lanƙwasawa, kusurwar lanƙwasa, kusurwar juyawa da sauran bayanai.Bayan tabbatarwa, ana iya aiwatar da aikin lanƙwasawa ta atomatik

Jerin babban sashi

| A'a. | Suna | Alamar |

| 1 | Frame | Hikima |

| 2 | Kayan aiki | Hikima |

| 3 | Lankwasawa naúrar | Hikima |

| 4 | Tsarin CNC | Hikima |

| 5 | Servo motor | Hikima |

| 6 | direban Servo | Hikima |

| 7 | Jirgin kasa | Hikima |

| 8 | Ƙwallon ƙafa | Hikima |

| 9 | Mai ragewa | Taiwan |

| 10 | Mai karyawa | Schneider |

| 11 | Maɓalli | Schneider |

| 12 | Bangaren lantarki | Schneider |

| 13 | Kebul | Yiku |

| 14 | Maɓallin kusanci | Omron |

| 15 | Mai ɗauka | SKF/NSK/NAICH |

4) Zane, ƙera, dubawa da shigar da kayan aikin injin sun cika ka'idodi masu zuwa.

1, GB17120-1997

2, Q/321088JWB19-2012

3, GB14349-2011

Abubuwan da aka gyara da lissafin kayan aiki

| A'a. | Suna | Qt. | Magana |

| 1 | Akwatin kayan aiki | 1 | |

| 2 | Sanya kushin | 8 | |

| 3 | Ciki hexagon spanner | 1 saiti | |

| 4 | Gun mai mai da hannu | 1 | |

| 5 | CNC tsarin manual | 1 | |

| 6 | bude spanner | 1 |